Anergy has a patent pending over the High Temperature Pyrolysis Process as well as holding several patents over parts of the process.

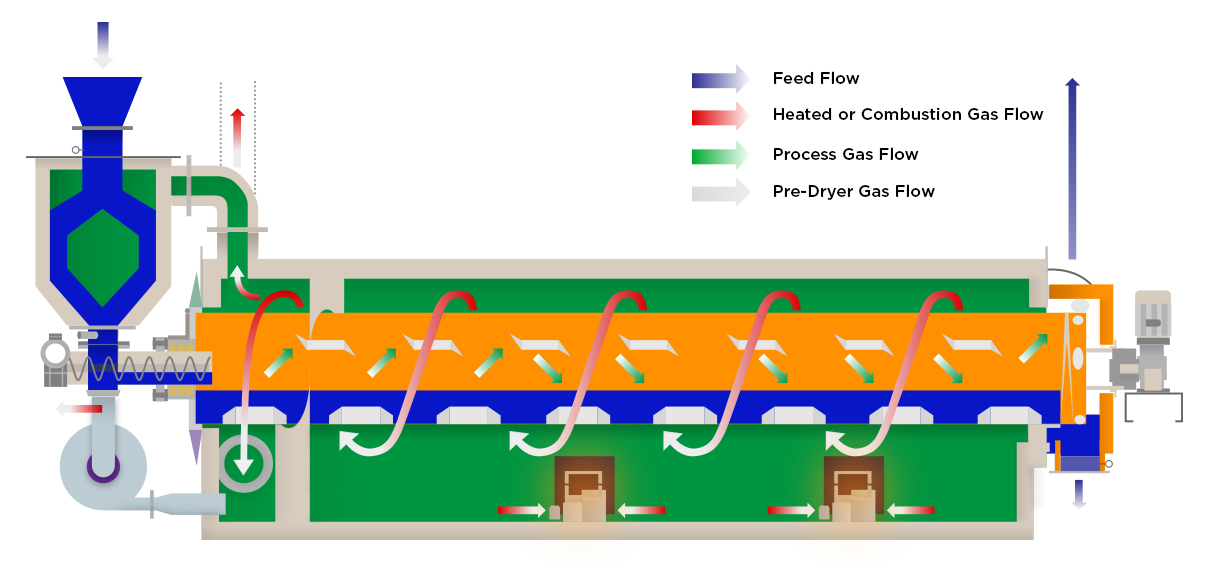

Anergy manufacturing and delivery strategy is to categorize the equipment into various independent equipment performing a specific functions, which we called subsystems.

Each subsystem will have its own individual local control panel to perform its functions such that it can be tested in Anergy's manufacturing facility. This will minimize the time required on site in troubleshooting and installation. The following are the core subsystems that are provided by Anergy:

With equipment in over 50 countries Anergy is already well set up to provide spare parts and support across the globe.

Anergy can assist with monitoring of the plant performance and optimise the operation by reviewing the plant data to suggest improvement.