We have developed our waste to energy system using high temperature pyrolysis; this is the point of differentiation. Pyrolysis is the thermochemical decomposition of organic materials at elevated temperatures with no oxygen present.

It is a superior and efficient power generation process further advantaged with patented and innovative feedstock preparation, gas optimisation and operating processes. It has additional revenue streams from biochar as a by-product.

Only Anergy’s High Temperature Pyrolysis converges on all the trends providing the ultimate value for customers.

| Renewable | Baseload Power | Matching Scale | Distributed Power | Widely Applicable | |

|---|---|---|---|---|---|

| Anergy High Temperature Pyrolysis | ✔ | ✔ | ✔ | ✔ | ✔ |

| Biomass Incineration / Gasification | ✔ | ✔ | ✘ | ✘ | ✔ |

| Aneaerobic Digestion / Landfill Methane | ✔ | ✔ | ✔ | ✔ | ✘ |

| Hydro Power | ✔ | ✔ | ✔ | ✘ | ✘ |

| Coal / Nat Gas / Oil | ✘ | ✔ | ✔ | ✘ | ✔ |

| Wind and Solar | ✔ | ✘ | ✔ | ✔ | ✔ |

| Simple Pyrolysis | ✔ | ✔ | ✔ | ✔ | ✘ |

| Diesel Generators | ✘ | ✔ | ✔ | ✔ | ✔ |

| Nuclear | ✘ | ✔ | ✔ | ✘ | ✘ |

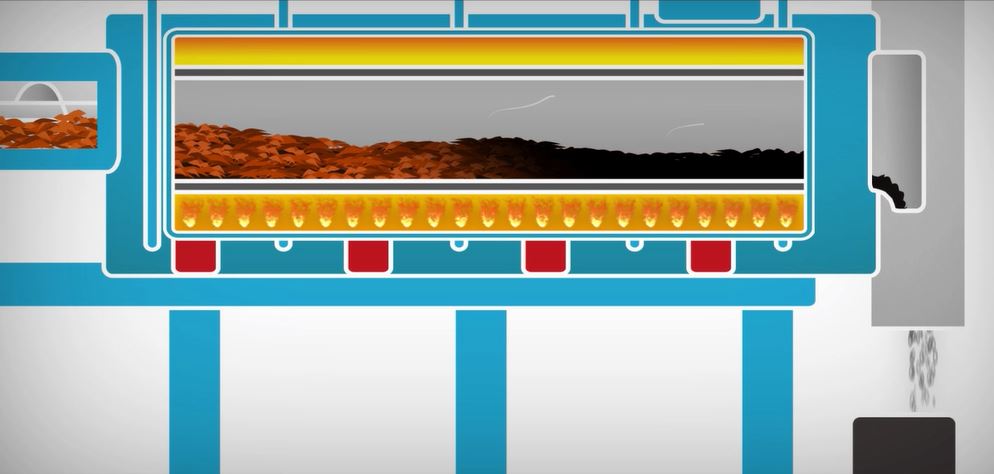

The unique design of the Anergy kiln allows the twin objectives of high product temperature and zero air ingress to be possible.

Most commercial processes operate on spectrum between pyrolysis and gasification where they attempt to balance air and temperature.

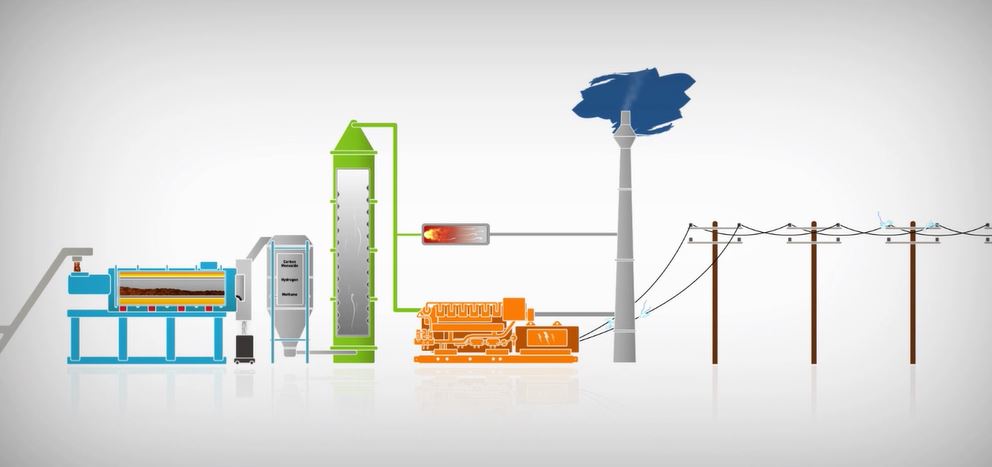

The feedstock is loaded into a hopper and transported along a conventional feed screw into the pyrolysis unit where the process begins.

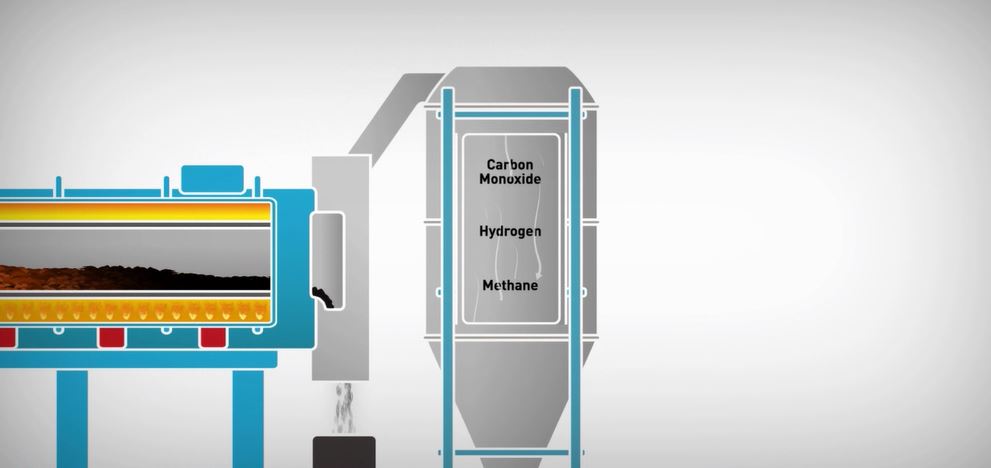

The pyrolysis of the woodchips occurs in a slow revolving Oxygen free heat tube. This heat tube is heated indirectly by a series of gas burners, converting the woodchip into char and unrefined gas. From the exit of the pyrolysis unit there are two streams, one gas and one solid.

The solid char stream is stock piled for use in “Bio Char Applications” as a secondary combustion agent or as activated carbon. The syngas goes through a reforming process to convert the long chain carbon into more useful hydrocarbons such as methane plus carbon monoxide and hydrogen.

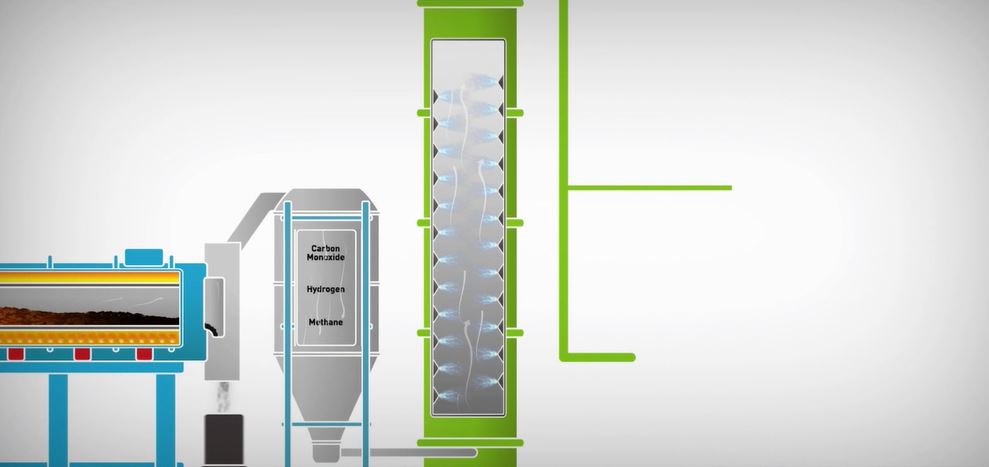

This gas then passes through a scrubbing system to remove dust and tars to become a clean syngas fuel.

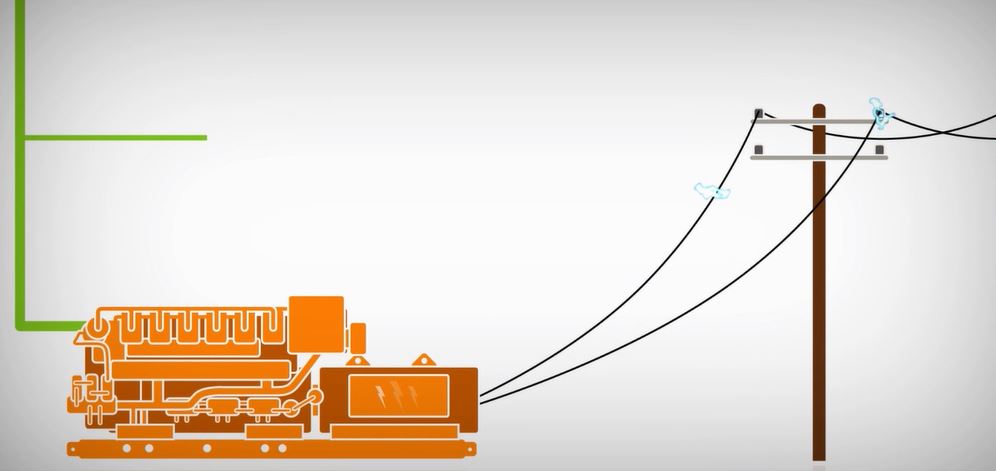

The syngas powers a series of engines, similar to those used in gas busses, which in turn spin alternators to create electricity to be used on-site or exported back into the grid.

The exhaust gas from the engines, is then dispersed. Any excess gas not used by the engines is burnt in an enclosed combustor and dispersed. This exhaust gas is the same as that produced by the engines.