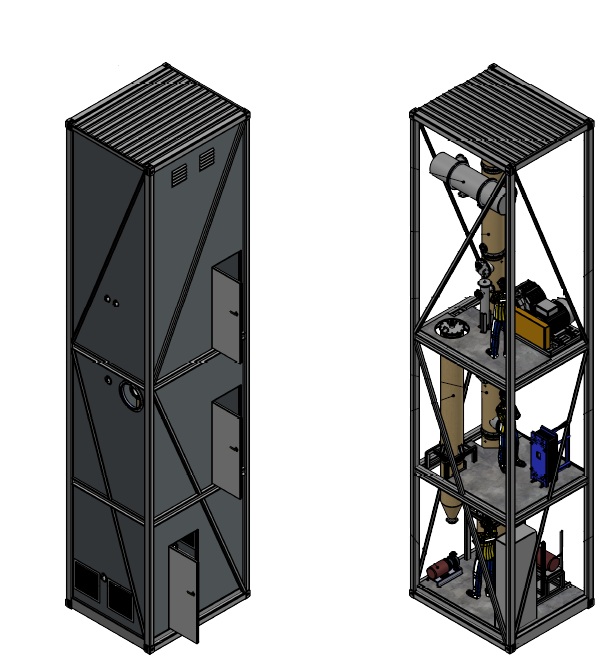

The GCU is a gas clean up unit that functions to clean the raw syngas produced from the HTP process. Anergy’s GCU subsystem consists of a four-part process utilising a conditioner, scrubber, polisher and dehumidifier.

The GCU removes unwanted compounds present in the syngas, which include dust, tars and inorganic compounds. This ensures that the syngas delivered is clean and fit for downstream applications, including for export and process sustainability.

The common GCUs in industry include, but are not limited to, scrubbers, conditioners, absorbers/filters and distillation columns.

Anergy’s GCU is a scrubber type which consists of a four-part process:

Conditioner

Scrubber

Polisher

Dehumidifier

Syngas from the kiln is sent into the conditioner to be quenched. This quenching process also removes some dust, tars and some organics from the syngas stream as an added benefit. Liquor exits from the bottom of the conditioner, and a cleaner syngas system exits to the scrubbing column.

The bulk of the cleaning process occurs within the scrubber column. Syngas enters the scrubber and is sprayed with incoming water or liquor. As the gas moves upwards, it collides with spray water droplets. This effect causes contaminants to be removed from the incoming syngas stream and the contaminated water (scrubbing liquor) collects at the bottom of the column. The use of chemical dosing into the scrubber to selectively remove certain impurities is also possible, to ensure that the syngas is truly well cleaned of impurities and contaminants.

The scrubbed syngas then moves up into the polisher to be further cleaned. Additional removal of residual tars, fine dust and organics not captured by the conditioner and the scrubber. In a way, this acts as a final layer of check and cleaning before the syngas is passed into the dehumidifier.

Finally, the cleaned syngas enters the dehumidifier. Chilled water cools the cleaned syngas to a low enough temperature and this allows for water to condense and be removed as a liquid stream. The clean syngas void of water then exits the dehumidifier.

While the HTP process is able to produce superior quality syngas, it still contains some unwanted composition that could lead to environmental impact. Anergy recommends the addition of GCU subsystem for clients that require, but not limited to:

Syngas for export

Syngas for process sustainability

Use of syngas for downstream processes

The cleaned syngas have higher calorific value than dirty syngas. This leads to a better economic and sustainability applications. In addition, it also helps to have cleaner emissions upon combustion.

Anergy’s GCU subsystem provides a robust solution for delivering a more efficient and cleaner syngas product. A cleaner syngas offers cleaner emissions, reduction in costs and enhances process and system efficiency.

Anergy’s GCU subsystem cleans the syngas of impurities and contaminants before it reaches downstream applications.

Anergy recommends the GCU subsystem to be used pre-combustion because the removal of inorganics such as nitrogen, sulfur and even chloride pre-combustion is far easier than post-combustion because these compounds can form harmful oxides when burnt.

Capturing these gases after combustion requires much more complex equipment and processes, unlike pre-combustion. These harmful gases also contribute to emissions failing to meet standards. The clean-up from Anergy’s GCU subsystem reduces harmful emissions, minimises environmental impacts, protects downstream processes and enhances overall process efficiency.

Cleaned syngas can be recycled to sustain the HTP process, which enables a carbon-zero solution for interested clients. By reducing the reliance on external sources of fossil fuels such as natural gas or LPG, it promotes a circular carbon pathway where carbon is reused within the process instead of being released as emissions.

Anergy’s GCU subsystem features a closed-loop scrubbing system that minimises wastewater generation and process water wastage where scrubber liquor is continuously filtered and recycled. This promotes environmental friendliness, process efficiency and cost-savings. In addition, water that is condensed from the dehumidification process is also used for the scrubbing and polishing of the syngas.