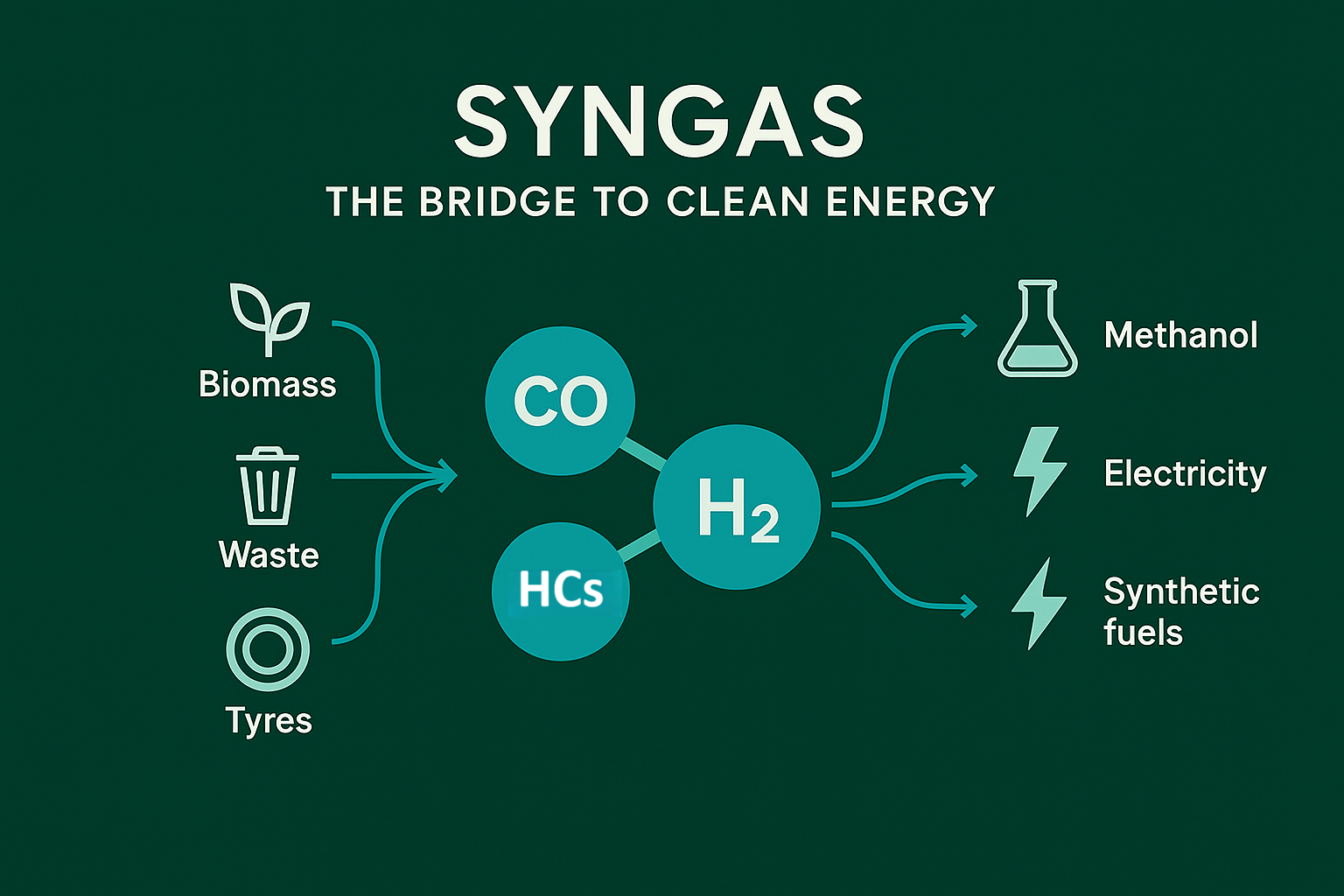

Syngas or synthetic gas is a gas mixture of hydrogen, carbon dioxide, carbon monoxide and hydrocarbons. It is generally produced in processing plants, including thermal processing plants, as a result of reactions or thermal processes.

Syngas is a product from Anergy’s HTP process, and it can be converted into useful products.

Syngas can be used as an energy source for heating, or it can be converted into useful products such as electricity or fuels.

Syngas is a gas mixture of hydrogen, carbon dioxide, carbon monoxide and hydrocarbons which sometimes is referred to as fuel gas.

It should not be confused with SNG (synthetic natural gas) which is mainly made of methane, CH4.

Traditionally, syngas is produced from fossil fuels such as coal and natural gas. With renewable technologies such as pyrolysis and gasification, syngas nowadays can also be produced from biomass, MSW and even waste tyres and plastics.

Syngas may be used to produce liquid fuels through Fischer Tropsch reactions. Hydrogen may also be extracted from syngas.

One of the more traditional ways of syngas application is to produce electricity with heat as a by-product.

Contact Anergy today to talk about your businesses waste-to-energy solutions

|

Syngas from HTP |

Syngas from other thermal processes |

Fossil Fuels |

|

Renewable power from waste with higher electricity production |

Renewable power from waste |

Non-renewable power |

|

Conversion of harmful and non-biodegradable waste to useful products |

Conversion of harmful waste to useful products |

Depleting the finite amount of fossil fuels |

|

Cleaner emissions |

Combustion produced toxic gases, NOx, SOx |

Combustion of fossil fuels will produce SOx, NOx and greenhouse gases. |

|

Decarbonisation through the production of biochar and cleaner emissions |

No avenue for biochar production. |

No decarbonisation solution with the use of fossil fuel. |

Waste that would otherwise be collected and sent to landfills could be utilised for power generation.

Waste from biomass, end-of-life tyres, MSW, etc. are produced on a daily basis by human activity. Landfill is diminishing and new solutions are required.

The syngas from HTP is richer and thus has the potential to produce higher electricity output as compared to syngas from other thermal processes.

Collection of non-biodegradable wastes, such as tyres and plastics, will accumulate in landfills and create health hazards.

PFAS or forever chemical has the potential to be destroyed through the HTP process.

The HTP has the capability to convert these wastes into syngas which can be utilised for power or fuel generation.

Combustion of syngas from HTP produces cleaner emissions.

The syngas will undergo cleaning and scrubbing processes to remove the inorganics, dust and tars prior to the conversion of the syngas. As such, the emissions as a result of the combustion of the cleaned syngas will be cleaner and will minimise the NOx and SOx formation.

With the right feedstock such as biomass and tyres, the HTP process will produce biochar that can be sequestered for decarbonisation.

Similarly with the cleaner emissions, it can also reduce the carbon emission assisting the environment to achieve carbon negative.

Syngas’ components are combustible in nature and upon combustion, energy will be released.

This is the basis for the syngas produced from gasification or incineration process whereby the syngas temperature is high enough through the combustion of the syngas to produce steam for steam turbine operation in generating electricity.

Similarly in the HTP process, as the HTP is done under no oxygen condition, the syngas will not combust on its own. The richer syngas is instead being combusted in engine generator(s) whereby the combustion air can be controlled for a more efficient electricity production and cleaner emissions.

Slight modification is required on off-the-shelf engines in order to be able to accept syngas as fuel.

Off-the-shelf engines generally run on regular fuel such as natural gas, LPG or diesel.

The combustion of the fuel will produce kinetic energy for electricity production with heat as a by-product.

While syngas can be extracted from wastes that otherwise would be unusable in landfills, ultimately syngas is a combustible gas.

It cannot be released into the environment as it will be a safety hazard. Its conversion to products such as electricity or fuel still yield flue gas such as CO2, which is a greenhouse gas.

Syngas does not completely eliminate the release of greenhouse gases into the environment. However, it helps to reduce the reliance on fossil fuels as an alternative fuel source.

The HTP process will offer a syngas that has higher energy content and a more efficient conversion into useful products.

At the same time, the gas clean-up process prior to the conversion of syngas will make the emissions from the combustion of the syngas to be relatively cleaner, minimising the NOx and SOx in the flue gas.

Syngas could produce a variety of compositions and it is difficult to produce a consistent syngas output especially in the case whereby the feed input is a mixture, for instance MSW, rather than a homogeneous feed input.

The variety of input will create non-consistent outputs which make the operation difficult due to the non-steady state conditions.

Syngas, generally, has lower calorific value than standard fuel such as natural gas and LPG. Most off-the-shelf equipment caters for the standard fuel and anything with syngas utilisation will require “custom made” solutions.

As syngas composition depends on the feed input, it sometimes contains contaminants such as sulphur compounds and/or chlorides which could be toxic upon combustion

The syngas from Anergy’s HTP process is superior as compared to syngas from other thermal processes.

Prior to any utilisation of the syngas, the syngas will undergo a 4-stage cleaning process through Anergy’s GCU to remove any inorganics, tars, dust and moisture.

The syngas from Anergy’s HTP process can be recycled to sustain the process once steady state operation is reached. This is generally about 20-50% of the syngas produced.

The remaining syngas is available for conversion into useful products such as electricity or be converted into fuel such as Dimethyl Ether (DME) or other fuels through Fischer Tropsch reaction.

Contact Anergy today to discuss your business needs when it comes to Syngas.